Pickup coils have an intensive use in electric guitars. Apart from guitar application, such coils are used to convert any form of energy into electrical energy. Basic pickup coil consists of magnets, bobbin and copper wire. Magnets are alloy which are generally in the center of the bobbin and the wire is wrapped about the magnet for which the bobbins are been used. For pickup coils the main design is high numbers of turns of fine wire generally 42 or 43 guage. When fine wire are to be wound some special care is to be taken.

In most of the case the turns are in high value around 6000 to 12000 turns and so the speed of winding should be high. The shape of the pickup coil is generally rectangle and when winding is done on the rectangle shape bobbin, the tension becomes uneven within one turns. At two locations the wire is pulled intensively and at two bobbin positions the tension is relieved. For such a winding profile with fine wire wound, the tension becomes important role. So the best choice of winding machine for winding pickup coil is high speed automatic programmable winding machines alongwith graduated tensioner units for fine setting of tension. Using programmable pickup coil winding machine will help in controlling the winding speed alongwith soft start and soft stop. With soft start features available in machine, the braking of wire is avoided or even elongation of the fine wire is avoided. And using fine adjustable tensioner unit the possibility of braking of wire is also avoided alongwith increase in quality winding.

Acme mechatronics, Inc. offers AEX-01 or AEX-02 alongwith graduated tensioner unit to wind guitar pickup coils.

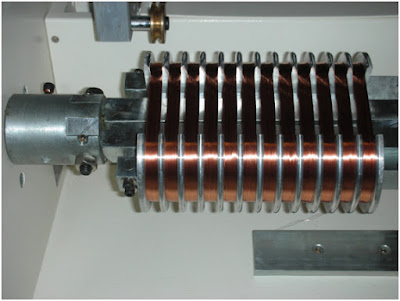

Below picture show the two coils as a time of guitar pickup coil. This machines has the capability to program most of the parameters like wire guage, winding width, starting point of the turns, soft start, soft stop, speed, etc.

Many times when the coil is wound, due to the pressure of wound turns, the bobbin flange expands which affects the functionality of the pickup coil so to avoid the expansion of the bobbin flanges additional accessory is used which will give support from the other side of the bobbin and this accessory is termed as tail stock. Not only this helps to avoid expanding of the bobbin flange but also it helps in quick loading and unloading of the bobbin.

For more information and inquiry please contact us.